Products

Products

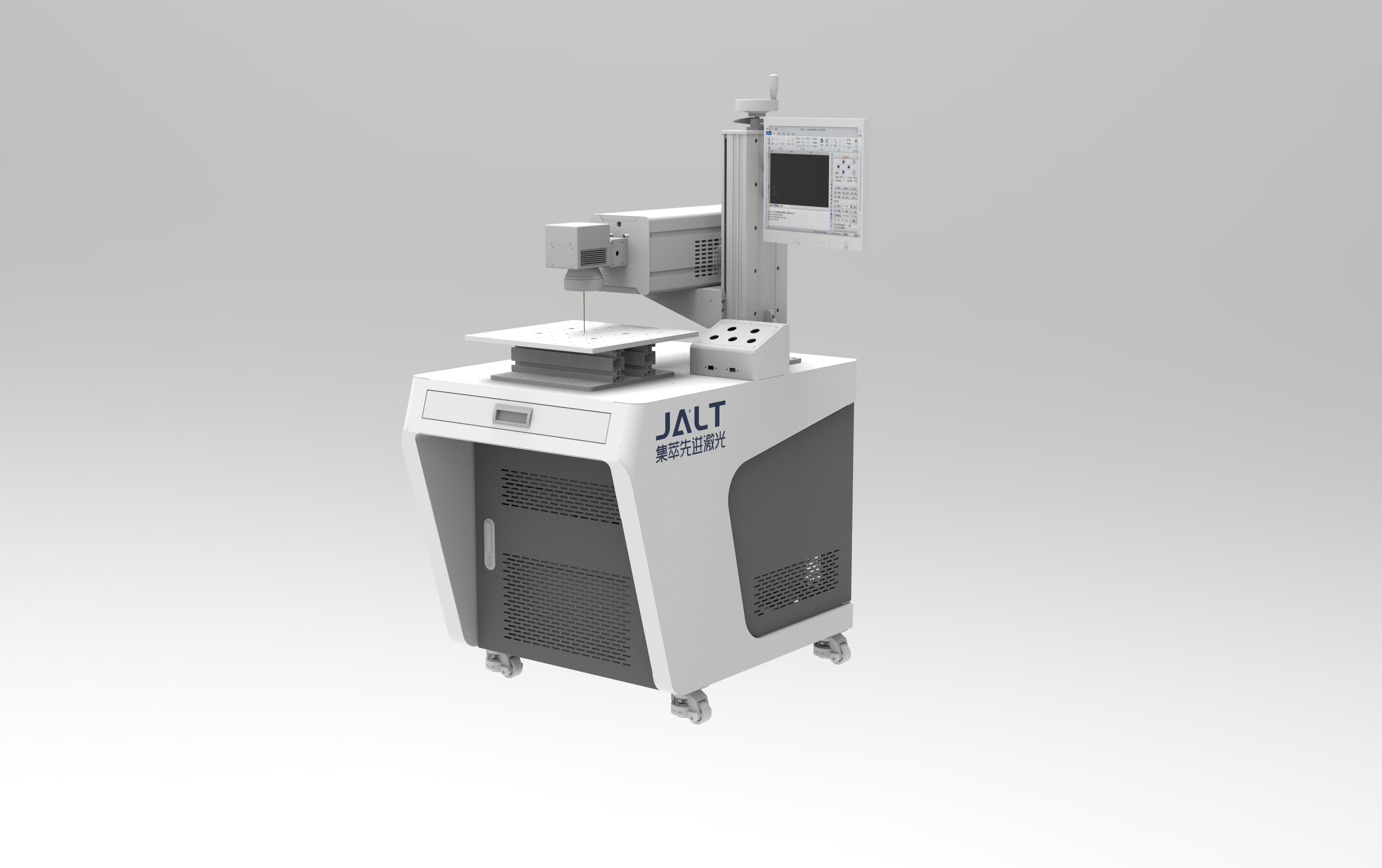

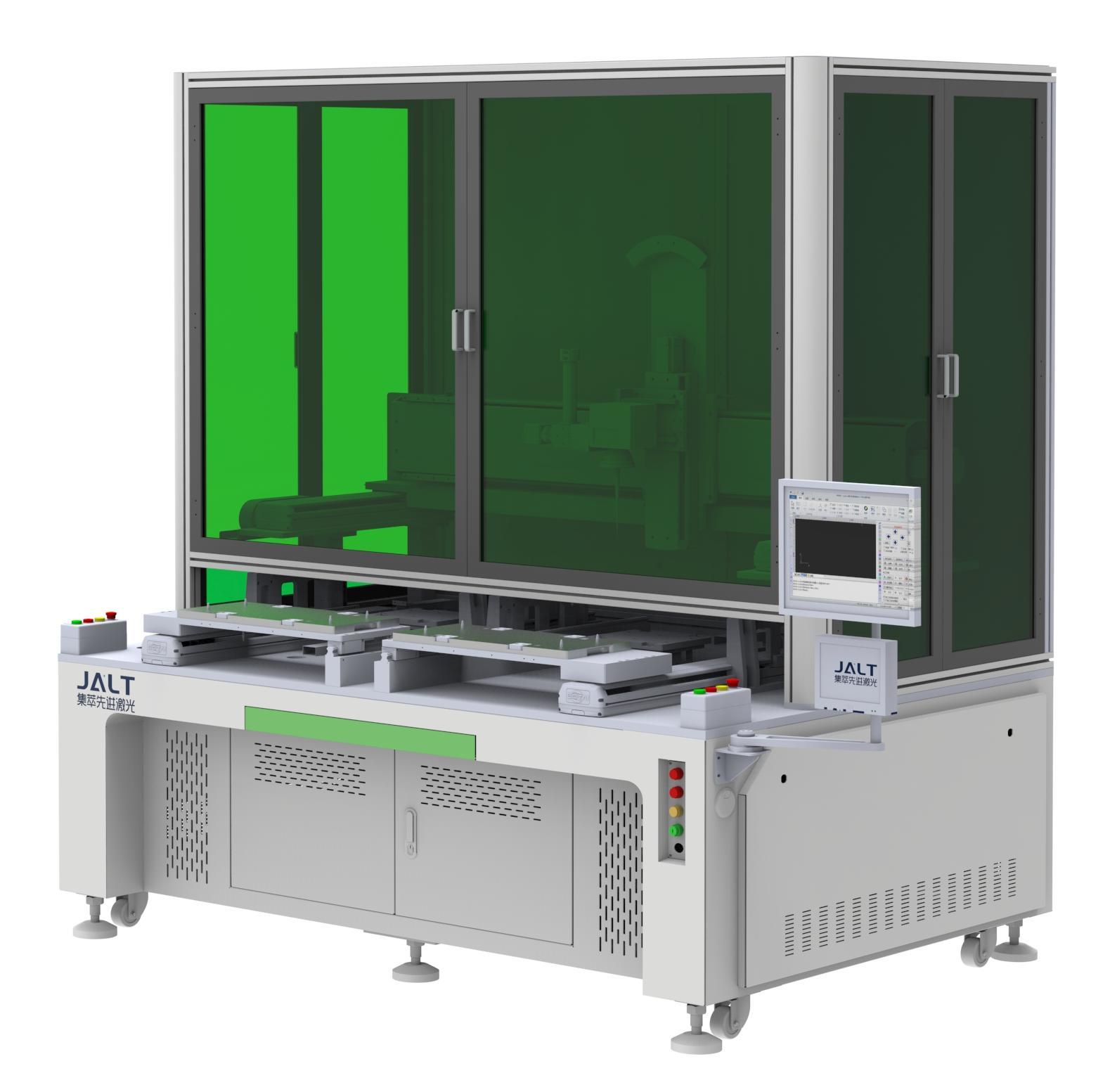

Plate surface defect detection equipment

Classification:

Equipment features:

- Product parameters

- Application fields

-

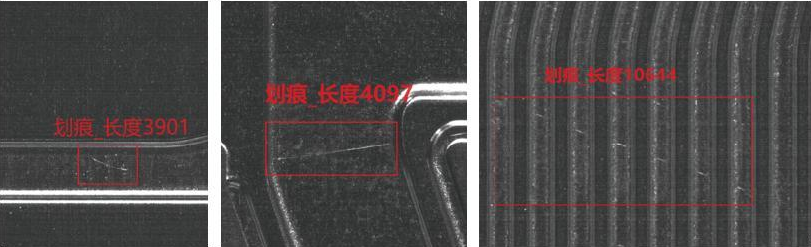

The JL-24-IN-DF three-dimensional polar plate size detection instrument is a laser online detection device that can quickly identify surface defects and flaws on polar plates, including scratches, uneven points, and stains, and quickly screen and remove unqualified polar plates. The device can be integrated into an automated detection production line for batch loading and unloading, intelligent detection, and intelligent sorting based on results. It can also generate detection logs to analyze changes in production yield and guide process improvement. Product Features: The device uses a detection technology that combines deep learning with traditional image processing to achieve efficient detection of surface defects and flaws. The device uses a self-developed and optimized neural network model to improve the efficiency of sample training and the accuracy of defect re-identification. The device uses a high-resolution optical imaging system and a high-precision motion control platform, combined with a large depth-of-field lens, to ensure high fidelity optical imaging. The software has a high degree of openness, allowing for customized functional modules based on user working conditions, and can communicate and interact with the user's existing MES system.

Project

Technical Index

Optical Principle

Imaging, Image Processing

Sample Size

600*400mm

Recognition Resolution

3.5um

Detection Speed

≥50mm/s

False Negative Rate

≤1%

Equipment Size

1500mm*1400mm*1800mm

Equipment Weight

800kg

Power Requirements

220VAC

-

Control of the quality of the bipolar plates in the production of fuel cell stacks; Control of the quality of the bipolar plates in the production of PEM electrolyzer stacks;

Online control of surface defects and flaws in key materials in other fields.

Key words:

Plate surface defect detection equipment

Related Products