Solution

Hydrogen fuel cell

With the layout of China's hydrogen fuel cell vehicle demonstration city cluster project, China's hydrogen fuel cell vehicle industry has entered a fast lane of development. It is expected that by 2030, there will be more than 1 million hydrogen vehicles installed, and hydrogen fuel cell vehicles will show a trend of coexistence and development of various models such as light vans, buses, light trucks, medium and heavy trucks, and passenger cars. Laser technology is applied in the entire process of hydrogen production, storage and utilization in the fuel cell industry.

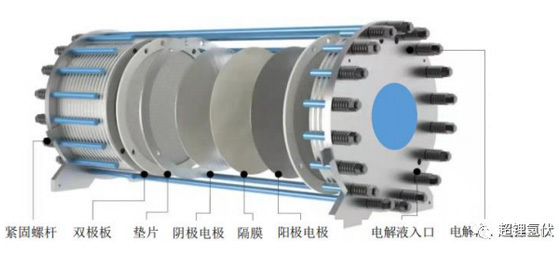

1) Hydrogen production stage

Laser welding: Electrolyzer cell frame and plates, electrolyzer nickel mesh plates, etc.;

Laser cleaning: Electrolyzer plates, etc.;

Laser cutting: Diaphragm (PPS fabric), electrode mesh/plate, cell frame flow channel, cell frame gasket laser cutting, etc.

2) Hydrogen storage stage

Laser welding: Type IV hydrogen storage bottles plastic, metal hydrogen storage bottles, hydrogen storage and transportation pipelines, etc.;

Laser cleaning: Metal hydrogen storage bottle welds after welding, etc.

3) Fuel cell

Laser welding: Titanium alloy metal bipolar plates, 316L stainless steel bipolar plates, graphite composite bipolar plates, etc.;

Laser cleaning: Cleaning of titanium alloy bipolar plate surface, cleaning of 316L stainless steel bipolar plate surface, etc.;

Laser cutting: Titanium alloy metal bipolar plates, 316L stainless steel bipolar plates, composite bipolar plates, CCM ultra-fast cutting, frame membrane cutting, etc.;

Laser detection: Detection of surface micro-cracks of bipolar plates, etc.;

Laser marking: Bipolar plate marking, stack marking, etc.