Solution

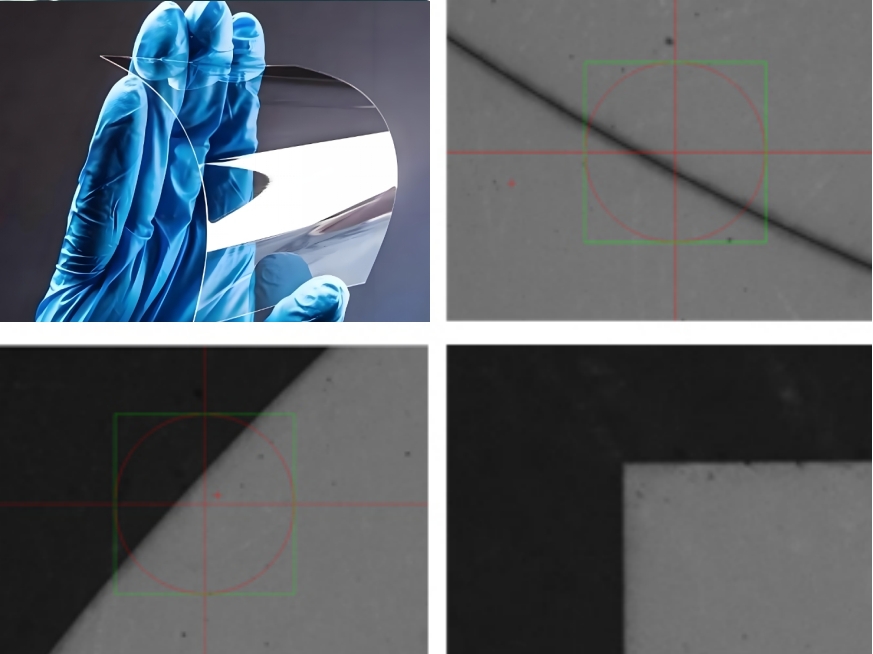

UTG glass

Characteristics of UTG Glass

- Extremely Thin Thickness: Typically 30-100 micrometers; traditional mechanical cutting easily leads to breakage or edge defects.

- High Hardness and Brittleness: Avoid thermal stress concentration leading to microcracks.

- High Surface Flatness Requirements: After cutting, smooth edges must be maintained to avoid affecting subsequent processes (such as bonding, coating).

Advantages of Laser Cutting UTG

- Non-contact Processing: Reduces mechanical stress and lowers the risk of breakage.

- High Precision: Can cut complex shapes, suitable for micrometer-level structures.

- Controllable Heat Affected Zone (HAZ) : Ultrafast lasers (such as femtosecond, picosecond) can minimize thermal damage.

Jiangsu Jicui Advanced Laser Technology Co., Ltd.

Copyright: Jiangsu Jicui Advanced Laser Technology Co., Ltd.

Address: Building A, Longgang Science Park, No.1 Hengyuan Road, Nanjing Economic and Technological Development Zone

Telephone:025-68790650/18951875203

Mobile website

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.