Solution

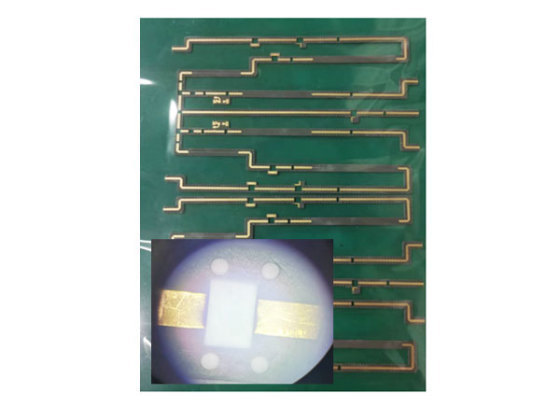

Rogers board cutting

Rogers PCBis a key process in the manufacturing of high-frequency circuits (such as 5G antennas, radar, and RF modules). Rogers materials (such as the RO4000 and RO3000 series) mostly use ceramic-filled PTFE (polytetrafluoroethylene) or hydrocarbon substrates, which have low dielectric loss and high stability, but are heat-sensitive and prone to delamination.

Material Composition:

- Substrate: PTFE (polytetrafluoroethylene) + ceramic particles (such as RO4350B containing ceramic fillers) or hydrocarbons (such as RO3003).

- Copper Foil Layer: Surface copper clad (thickness 18μm~70μm).

Laser Selection

- Ultraviolet laser (355nm) :

- Advantages: Cold processing characteristics reduce the heat affected zone (HAZ), suitable for fine cutting.

- Applicable Scenarios: Thin plates (thickness ≤1mm), high-precision graphics (such as microstrip lines, antenna arrays).

- Ultrafast laser (picosecond/femtosecond) :

- Advantages: Ultra-short pulses (<10ps) with almost no heat diffusion, avoiding PTFE melting.

- Applicable Scenarios: Ultrathin plates (<0.5mm), military-grade products requiring zero delamination.

Jiangsu Jicui Advanced Laser Technology Co., Ltd.

Copyright: Jiangsu Jicui Advanced Laser Technology Co., Ltd.

Address: Building A, Longgang Science Park, No.1 Hengyuan Road, Nanjing Economic and Technological Development Zone

Telephone:025-68790650/18951875203

Mobile website

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.