News

Exploring the innovative development of metal forming machine tool manufacturing

1. Overview

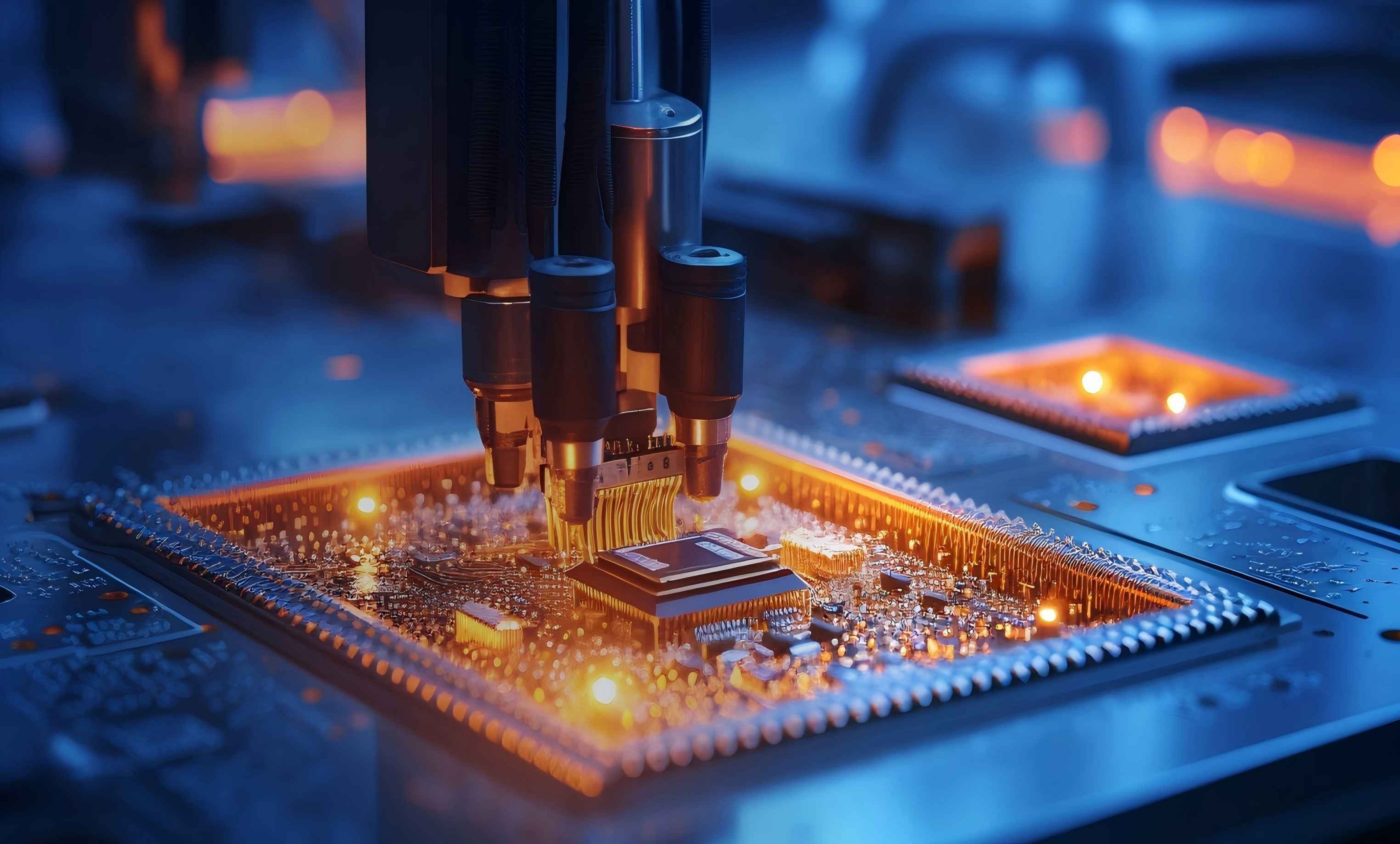

The metal forming machine tool manufacturing industry is at the core of industrial development. With the rapid advancement of technology, this field is continuously innovating and developing. Metal forming machine tools are mainly used for processing metal materials, including cutting, bending, milling, and turning processes, and are widely applied in various industries such as automotive, aerospace, electronics, and energy.

2. Driving Forces of Innovative Development

1. Technological Progress: The continuous advancement of technologies such as CNC technology, automation technology, artificial intelligence, and the Internet of Things provides a constant driving force for metal forming machine tool manufacturing.

2. Market Demand: As various industries increase their demand for high precision, high efficiency, and high-quality products, the performance requirements for metal forming machine tools are also becoming higher.

3. Manifestations of Innovative Development

1. Intelligence: Metal forming machine tools are developing towards intelligence. Intelligent machine tools can achieve autonomous processing and automatic adjustment, improving processing accuracy and efficiency.

2. Efficiency: High-efficiency machine tools can significantly improve production efficiency and reduce production costs to meet market demands.

3. Green and Environmental Protection: With the increasing awareness of environmental protection, metal forming machine tool manufacturing is also developing towards a more environmentally friendly direction. For example, using more eco-friendly materials, reducing noise, and minimizing waste.

4. Customization: As the demands of various industries diversify, metal forming machine tools are also moving towards customization. Specific machine tools are customized according to customer needs to meet specific processing requirements.

4. Challenges and Countermeasures

1. Technical Challenges: There is a need to continuously develop new technologies to improve the performance and precision of machine tools.

2. Market Challenges: It is necessary to understand market demands and adjust product structure and direction based on market needs.

3. Competitive Challenges: There is a need to enhance competitiveness through technological innovation, product quality, service improvements, etc.

Countermeasures: Increase investment in research and development for continuous innovation; strengthen market research to understand market demands; improve service quality to enhance customer satisfaction.

5. Conclusion

The innovative development of metal forming machine tool manufacturing is an inevitable trend in industrial development. In the face of challenges, continuous innovation is required to improve technological levels and product quality to meet market demands and enhance competitiveness. In the future, metal forming machine tool manufacturing will develop towards intelligence, efficiency, environmental protection, and customization.